When Jason Trembly was replacing the wood deck at his home, he had an “aha” moment. The Ohio University Russ Professor of Mechanical Engineering and director of the Institute for Sustainable Energy and the Environment thought: Instead of using a wood-plastic composite material—which tends to warp and oxidize and is difficult to recycle—why not create a composite material based on coal and coal byproducts that didn’t come with these drawbacks?

He went to the lab and soon formulated a potential product that was not only workable, but also economically feasible for the construction market. His next step? Submit an invention disclosure to OHIO’s Technology Transfer Office (TTO), which guided his provisional patent application.

The whole point of tech transfer, according TTO’s Director Bob Silva, is “getting our innovations into the marketplace for the good of mankind.” In Trembly’s case, it can mean sustainably using coal without releasing carbon into the atmosphere. Other efforts at TTO create therapeutics or medical devices that can save or improve lives. Ohio University has a strong track record when it comes to bringing technologies to market—licensing revenue topped $100 million over the past 10 years.

Three-time OHIO graduate Jason Trembly, BSCHE '03, MS '05, PHD '07, directs the Institute for Sustainable Energy and the Environment. Photo by Ben Wirtz Siegel, BSVC ’02

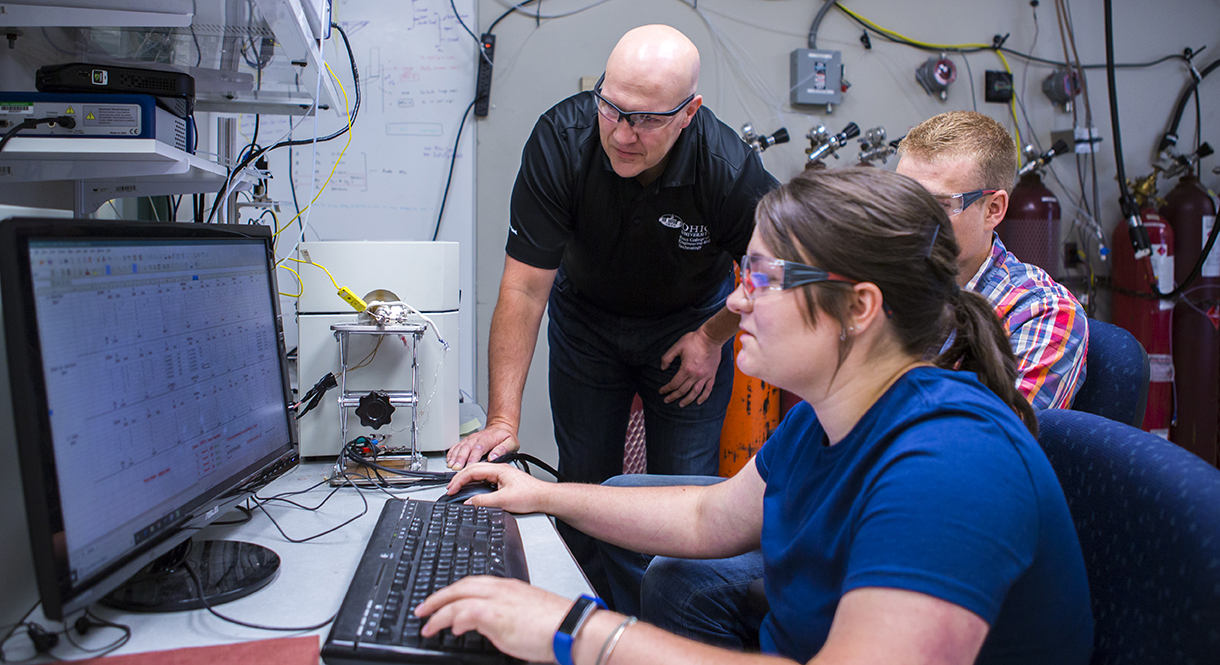

Today, Trembly and his team of students are continuing to test the material while the TTO negotiates rights to the technology with two companies, CONSOL Energy and Engineered Profiles. The latter is headed by mechanical engineering grad Mike Davis, BSME ’02, and his brother Brian Davis, BSCHE ’04, a fellow chemical engineering grad like Trembly, himself a three-time OHIO alumnus, having earned his doctoral degree in chemical engineering in 2007.

“We love to work with alumni (because) they make great partners,” says Silva. “They want the school to be successful, they want to be successful, and they are easy to work with. ... Everybody wins.”

Silva points out that bringing a technology to market takes, on average, eight years due to the effort involved in capturing, evaluating, protecting, marketing, and licensing the technology, whether through an existing company or a startup.

Trembly’s coal-wood composite technology has a good chance of making it to market, specifically because production costs are competitive and manufacturers are already positioned to produce it.

Trembly knows that very few ideas make it from lab to market, so he’s in academia for another important reason.

“Working with the students is a really fun and rewarding part of the job,” he says, “Honestly, (graduates are) our No. 1 product."

Feature photograph: Faculty and student researchers in the Russ College’s Institute for Sustainable Energy and the Environment are developing composite decking boards from coal, backed by $2 million in support from the U.S. Department of Energy and industry partners. Photo by Ashley Stottlemyer