On land, along the ocean floor and buried underground there are thousands of miles of pipelines all over the world. These carbon steel tubes form vast networks, braving the elements to transport oil, gas, carbon dioxide and chemicals to meet global energy demands—but like any metal, they are prone to corrosion.

Corrosion leads to a decay of infrastructure. Whether it results in a nuclear meltdown, a bridge collapse or an oil spill, failing infrastructure can cause catastrophic damage to people and the environment. Predicting and combating corrosion is essential in preserving infrastructure, protecting the environment and mitigating economic consequences.

Ohio University’s corrosion institute has been solving corrosion-based problems and advancing the industry since 1993. The Institute for Corrosion and Multiphase Technology (ICMT) is a world leader in conducting corrosion research and the largest corrosion research facility of its kind in the world with a football field-sized laboratory.

With much of the U.S. oil and gas industry located in Texas, ICMT is a globally influential presence in Appalachia. ICMT works directly with industry partners in the U.S. and around the world, allowing students to play key roles in advancing research in the field that has an immediate impact.

The institute is part of the Russ College of Engineering and Technology, and has been honored with numerous awards including the Association for Materials Protection and Performance (AMPP), formerly National Association of Corrosion Engineers (NACE) International, 2021 Distinguished Organization Award. This award recognizes outstanding contributions in the field of corrosion science or engineering over a sustained period.

Forward-thinking sustainable solutions

Predicting and mitigating corrosion to protect the environment is something the Institute of Corrosion and Multiphase Technology has done since its inception. Through a new project centered around carbon transportation, ICMT has opened yet another avenue contributing to sustainable solutions. Ohio’s corrosion institute is one of just two laboratories in the world leading the research effort in corrosion in carbon dioxide (CO2) transmission pipelines.

According to the U.S. Environmental Protection Agency, carbon dioxide (CO2) capture, transportation and sequestration (CCS) is a set of technologies that can greatly reduce CO2 emissions from new and existing coal- and gas-fired power plants and large industrial sources—reducing greenhouse gas emissions, while enabling low-carbon electricity generation. CCS is a three-step process that includes:

- Capture of CO2 from power plants or industrial processes.

- Transport of the captured and compressed CO2 (usually in pipelines).

- Underground injection and geologic sequestration (also referred to as storage) of the CO2 into deep underground rock formations.

The ICMT Corrosion in CO2 Transmission JIP will focus on the transport step—studying and refining CO2 transmission pipelines to understand and mitigate corrosion. CO2 itself isn’t corrosive; it’s the contaminants leftover from the capture process that can degrade the infrastructure.

Distinguished Professor in the Department of Chemical and Biomolecular Engineering and ICMT Director Srdjan Nesic, Ph.D., says the work related to CO2 being safely transported has a lot of interest from major industries and will help the planet.

“With all the CO2 that has to be collected to save our planet from overheating and then transported and injected into the ground, we are looking at corrosion issues in such operations,” explained Nesic. “This has a direct link to the environmental, agenda and corrosion and is something that's of great importance for the environment.”

Large-scale lab, big impact

Much of the Institute for Corrosion and Multiphase Technology’s research revolves around the pipelines that transport oil and gas for energy and the pipelines that transport captured carbon dioxide. Most of these transport pipelines are made of carbon steel, a metal that is cheap to produce and easy to work with. Though they are cost effective, carbon steel pipelines are prone to corrosion caused by the presence of water in the produced fluids. Water and other contaminants like carbon dioxide, hydrogen sulfide, that are naturally present in oil and gas reservoirs react with the pipeline’s carbon steel internal surface, causing decay over time.

For nearly 30 years, researchers in the Institute for Corrosion and Multiphase Technology have been studying these natural forces that cause the corrosion of pipelines, in their West State Street facility. The facility’s large-scale, specialized equipment enables the testing and simulation of complex corrosion environments.

Ohio University students at the ICMT work on bench-scale equipment.

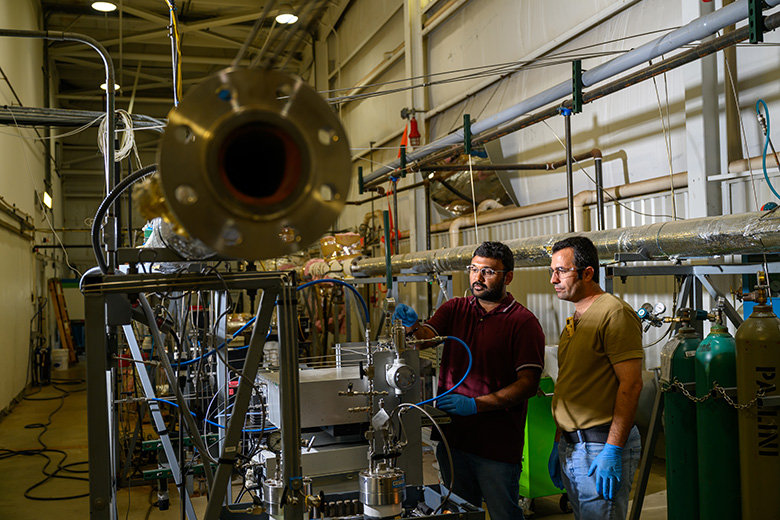

ICMT researchers examine a pressure gauge next to a multiphase flow loop.

Nesic says that the facility allows Ohio University researchers to create field-like conditions in a laboratory setting where they can control crucial variables while exploring causes of corrosion. The added control and stability of the experiments conducted in the lab lead to results and discoveries that are often impossible for oil and gas companies to attain in the field.

“That’s where we are unique—there’s no other lab that I know of that has such a large collection of pilot-scale equipment, where we can recreate the problems that they have in the field and study them appropriately,” said Nesic. “We have large lines and high-pressure vessels, and we use complicated, often poisonous gases and acids because that's what they have in the field, yet we do it in a controlled, safe, research setting where we can get the answers in a way that [those in the industry] cannot.”

The largest and some of the most important equipment in the facility are four multiphase flow loops capable of various temperature changes, pressure changes and flow controls. These large-scale systems simulate the multiphase flow of fluids in a transport pipeline using a looped system that continuously circulates the liquid and/or gas contents. The piping of the flow loops is made of more durable stainless steel to increase their longevity as research equipment—pieces of carbon steel are inserted through dedicated ports when testing for corrosion.

Professor of Chemistry and Biomolecular Engineering and ICMT Associate Director for Project Development Marc Singer, Ph.D., says flow loops are ideal for a variety of research projects in the realm of oil, gas and carbon dioxide transportation.

“We recreate the chemistry of the fluids and gases inside the pipeline, and measure the resulting corrosion on steel,” explained Singer. “One relatively crude but effective method is to expose a piece of metal, directly cut out of carbon steel pipelines, to the corrosive gas or fluid inside our flow loops for a given time, and to inspect the effect that water can have on the integrity of metal. It’s amazing what even little droplets of water can do to steel in a few months.”

The ICMT also houses an inclinable flow loop used to simulate vertical or angled pipelines as they would be positioned in the field. Additionally, the lab contains high pressure autoclaves capable of liquifying carbon dioxide and several smaller rooms where conducting bench-scale experiments is done in support of the institute’s industrial-scale work. Analytical instrumentation such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction, Raman microscopy, surface profilometry and a comprehensive range of electrochemical techniques help examine the effects corrosion even more precisely.

Cutting-edge research driven by industry needs

Beyond the state-of-the-art equipment found in its facilities, the Institute for Corrosion and Multiphase Technology’s close relationship with the industry also makes it unique. The problems that ICMT is seeking solutions to come directly from the industry. Nesic says that doing research for industry partners can make the stakes higher; but the work is guaranteed to always be relevant.

“We are almost entirely funded by the industry, which is quite unusual,” emphasized Nesic. “With industry funding, if you don’t perform, you’re done. It’s hard to get industrial funding, and if you don’t do well, [sponsors] will never come back, but we’ve been successful on that front. We have major companies who have been funding us for 30 years, and that’s only because we’ve been doing work that’s relevant for them and delivering what we promise.”

Organizations from around the globe look to ICMT to provide them with information and corrosion prediction tools to meet the demands of their business. The corrosion institute works with more than 30 industrial sponsors including most of the major oil and gas producers, chemical companies, steel manufacturers and service providers in the world.

ICMT's inclinable flow loop used to simulate vertical or angled pipelines as they would be positioned in the field.

An ICMT researcher works on bench-scale equipment.

Most of ICMT’s projects involve trying to understand the physical mechanism and corrosion processes, guiding industrial sponsors and educating them about potential issues in different environments and developing corrosion prediction software based on the research. The institute collaborates with both individual industry sponsors through proprietary research projects as well as consortia made up of multiple companies through joint industry projects (JIPs)

Currently, the institute’s two main joint industry projects are the Corrosion Center JIP led by Dr. Bruce Brown and the Corrosion in CO2 Transmission JIP led by Dr. Yoon Seok Choi. The Corrosion Center JIP has been ongoing for nearly 32 years studying the fundamentals of aqueous carbon steel corrosion including a variety of active projects, with several new projects being planned. The Corrosion in CO2 Transmission JIP is a newer venture focused on CO2 transmission, which Nesic says has generated a lot of interest from the industry.

A student-to-client pipeline

A large part of the Institute for Corrosion and Multiphase Technology’s mission is educating and training students who will go on to become leaders in the field of corrosion. Students are an essential part of both the proprietary research and joint industry projects—all projects are conducted by students and postdocs, supervised by project leaders under the direction of Nesic and Singer, but also younger faculty from the Chemical Engineering department: Dr. Sumit Sharma and Dr. Madhu Majji.

ICMT currently has around 25 students, mostly made up of Ph.D. students with a few undergraduate students. With the institute’s strong industry ties, Nesic says that Ohio University students have a big advantage when entering any corrosion-related industry. The more than 80 ICMT students who have graduated have all gone on to find success.

“We have graduated, a large number of students who have made it, very successfully, most of them in the industry—10% in academia, 90% in industry,” said Nesic “We prepared the students in a way that one cannot compete with because our students learn how to interact, and how to perform in an industry setting, they meet their future employers early on, and they get jobs with those companies that they do research for. They're doing really well, and we're very proud of them.”

As part of their education, students also act as representatives of the Institute for Corrosion and Multiphase Technology and Ohio University at semi-annual board meetings. Every six months, representatives from some of the most prominent oil, gas and carbon capturing companies in the world are invited to ICMT to review current research through presentations, tour the facilities and provide research direction for future testing. Students run these meetings, work directly with clients and present their research. Meeting with clients so frequently and learning from professors who advise them creates an incredibly effective synergy.

Nesic estimates that around a third of company representatives that come to the board meetings nowadays are ICMT alumni. He and Singer agree that this is a great dynamic, unique to the institute that is beneficial for students entering the industry—a student-to-client pipeline.

“Students are put on these projects and develop strong interactions with clients. It’s very good for professional development,” emphasized Singer. “After graduation, our students typically end up joining the corrosion teams of our own clients. They know what we’re capable of and often come back to Ohio University ICMT to help their new employer to solve their latest issues. This sounds like an effective business model.”

Ph.D. student Michael Hehemeku is currently working on the Corrosion in Carbon Dioxide Transmission JIP with a focus on studying the mechanisms causing corrosion in CO2 pipelines and creating a model for them. Hehemeku agrees that researching at ICMT is helping prepare him for a successful career.

“You get to really know what is happening,” explained Hehemeku. “We have representatives from the companies sponsoring the project come here every six months to hear the progress of the research. They make sure that we are researching the particular conditions that they have in the field—temperature, pressure, pH, everything. So, we replicate what is happening in the field. I think that is a good way to know what is happening in the industry.”