Why is the road all torn up? What could they possibly be doing? If those questions have ever crossed your mind, there’s a good chance the excavation is due to crucial pipe infrastructure being replaced.

Corroded and aging pipes are a major problem for departments of transportation across the United States. There are more than 90,000 pipes in Ohio alone, a great portion of which are deteriorating and need rehabilitation at a rate faster than they can be replaced. The usual procedure would be to close the road for an extended period, excavate it and replace the pipe—a headache for drivers and local businesses. Tearing up the road, however, could soon become less common.

Ohio University’s Ohio Research Institute for Transportation and the Environment is leading national research investigating a low-cost alternative to excavating and replacing corroded piping through using Cured-in-place pipe liners.

Research with national impact

The Federal Highway Administration’s National Cooperative Highway Research Program (NCHRP) recently awarded the Ohio Research Institute for Transportation and the Environment (ORITE) with $455,000 to conduct a three-year study centered around Cured-in-place pipe (CIPP) liners. The ORITE-led team was selected in a national competition with researchers at other universities and the private sector.

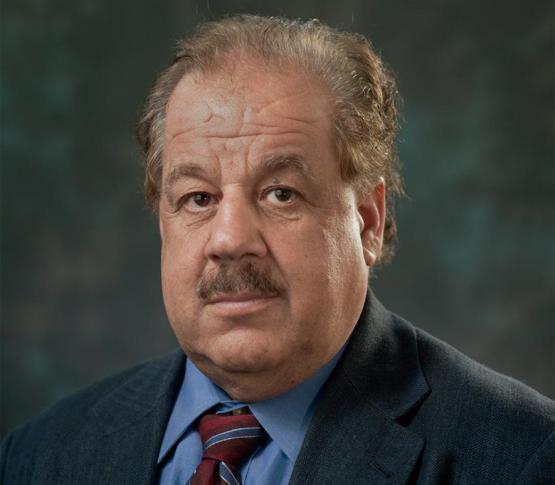

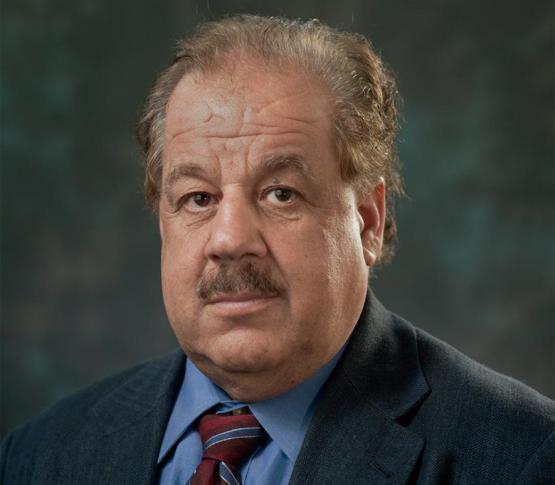

Ohio University Russ Professor of Civil Engineering and ORITE Vice Director for Business Development Shad Sargand, Ph.D., is the principal investigator of this project and leader of this internationally collaborative effort. Sargand says that the CIPP liner design being studied has the potential to become a national standard used by the American Association of State Highway and Transportation Officials (AASHTO). If the research is adopted by AASHTO, he estimates that CIPP rehabilitation will become much more common than the traditional method of tearing up roads.

“[CIPP liners] will be more acceptable with the engineering community,” said Sargand. “They prefer it economically, safety-wise and with the fact that they won’t have to tear up or close roads.”

Pipes deteriorate mainly due to water-based corrosion, but extreme temperatures and structural stress can also cause them to break down over time. U.S. departments of transportation are constantly working to address pipes that need rehabilitating, but funds are limited and digging up a road to get to crucial infrastructure is costly.

This is where CIPP liner rehabilitation comes into play. Felt or fiberglass tubes are placed inside an existing corroded pipe, infused with resin and hardened in place, creating a rigid shell inside of the pipe to reinforce it and prevent further deterioration. This presents a low-cost alternative to excavating the corroded pipe and installing a new replacement.

Ohio University researchers are developing an equation that will determine the minimum thickness of the liner required to create a durable pipe rehabilitation that will last for several decades. Once the equation is developed, and validated through experimental work at OHIO, manufacturers will be able to create effective liners in accordance with field conditions.

“All the work will be done at Ohio University at the Athens and Lancaster campuses,” emphasized Sargand. “But we’re developing and validating equations that apply to the whole nation. It’s not for us alone. It’s for Ohio. It’s national. The work we’re doing has national impact.”

ORITE continues tradition of national leadership

ORITE is one of the premiere research institutes in the United States studying pipes and culverts in transportation infrastructure. It has a history of more than 100 projects through the past four decades, and developing a guide for design, installation and testing for CIPP liners is only the latest endeavor in a long line of successes.

The ORITE team includes Sargand, along with ORITE Director and Associate Professor Issam Khoury, Professor Teruhisa Masada, and staff and graduate students. Sargand says that OHIO’s well-respected leadership in pipe research allowed them to bring researchers together from across the globe to collaborate on the CIPP project.

Partners include E.L. Robinson Engineering Co. in Columbus, Rehabilitation Resource Solutions in Hilliard, Olivier Thépot in Paris, France, and the Advanced Materials Center at the University of Minnesota – Duluth. Sargand says each of these industry and educational partners will help serve different functions in research and that most of them have OHIO alumnus connections.

“These people trust us to lead the project,” said Sargand. “We have brought together several researchers around the United States and internationally, and this team was developed specifically to do this work.”

Beyond Ohio University’s national leadership and expertise in transportation, environmental and geotechnical science and engineering, Sargand says that the pipe industry itself is very connected to the state of Ohio. This proximity makes industry collaboration and research efforts even smoother.

“The pipe industry is basically Ohio-based,” said Sargand. “Ohio has a leadership in the area of the pipe and the headquarters of most of the major pipe manufacturers are located in Ohio.”